About us

About us

Saturn S.A. - Alba Iulia, a company with private shareholders (the major shareholder being C.I.M.U. SRL from Cinisello Balsamo - MI, Italy), was founded in 1972 and over the years grew into one of the most important foundries of cast iron parts in Romania.

Being designed and built with the assistance of the German company BUDERUS WETZLAR, Saturn started production in 1975, using German machinery and technology based on German know-how.

The type of production we carry out includes:

- parts for machine tools (drums, casings, columns, fixed and mobile tables, vertical beams, faceplates, fixed and mobile crossbars, etc.);

- parts for automotive industry;

- parts for oil extraction installations;

- parts for elevators;

- measuring and control tables;

- parts for metallurgical equipment (ingots, casting bridges and funnels, shields for coke ovens);

- counterweights for machine tools, forklifts, cranes and travelling cranes;

- other parts (steering wheels, crowns, etc.).

- Length: 500 - 15.000 [mm];

- Weight: 80 - 40.000 [Kg].

More than 80% of our production is exported to EU countries, which demonstrates the confidence of our customers in the quality of our products and our ability to comply with international standards.

We insist upon quality, and to confirm this, we are EN ISO 9001:2015 certified by TÜV Süd - Germany. This certification demonstrates our firm commitment to providing the highest quality products and services.

Time frames

"The resilience and current positioning of the company can be appreciated as an overall success of the almost 10,000 employees it has had over time." (Virgil Decean – General Manager of Saturn between 1990-2021)

Over 50 years of history in casting iron involves several important periods, mentioned below:

The first stage (1972) - Designing a complex industrial establishment in Alba Iulia, namely a foundry specialized in castings for machine tools industry.

The second stage (1973-1975) - Construction and calibration of the project to the functional requirements. It was chosen the solution of casting large parts in chemically hardened cold molds, after a western expertise design, practically an import foundry was created, being designed and built with the assistance of the German company BUDERUS WETZLAR.

Production line 1

for castings between 80 and 1500 kg.

Production line 2

for castings between 1000 and 7000 kg.

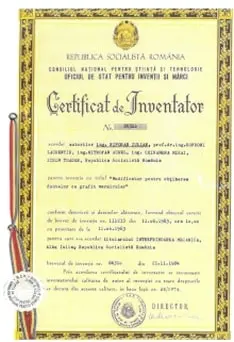

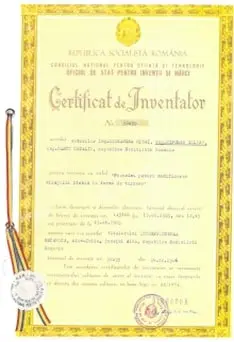

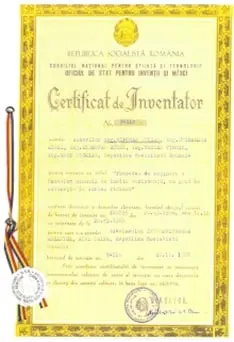

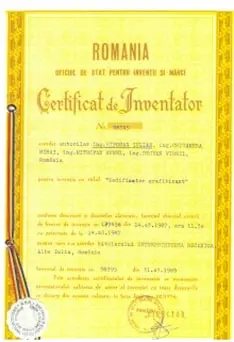

The third stage (1975-1989) - By the pressure of time and times, specialists were formed along the entire professional hierarchy - specialized workers, foremen, technicians and engineers for the production of castings. The production also had an upward dynamic and a permanent increase in the complexity of the casted parts, both in terms of geometry and functionality, as well as in terms of the materials from which they were made (1975-1980). The period of consolidation of the productive capacity was continued with professionalism between 1981 and 1989, the production achieved being on average 21,000 tons annually. Now, new brands of cast iron and processes for their industrial development, for which invention patents have been obtained, are assimilated into production. The fields of service have diversified, Saturn's portfolio also includes high-complexity landmarks from the metallurgical and energy industries, representative of the technological peak being the components of nuclear equipment.

The fourth stage (1990-1998) - Starting with 1990, the foundations are laid for the transition from the centralized economy to the market economy through a transition that brought great difficulties to the company. 1992-1993 saw the lowest production ever. Due to declining demand for machine tool castings, between 1992 and 1998 Saturn produced ingots and casting bridges for the metallurgical industry. The idea of ??re-launching the company started from the assessment of the lack of potential of the domestic market and the self-imposed obligation to find solutions to enter the Western market. In 1994, Saturn representatives paid a visit to Italy, to the Milan headquarters of UCIMU, the visit materialized in a collaboration agreement. This represented the beginning of production for export, the level increasing from one year to another, in 1999 approx. 30% of the production was exported. The last decade of the 20th century marks the foundry's confrontation with a pronounced decrease in the domestic production of machine tools and the adaptation of manufacturing on this background to the requirements imposed by foreign partners, especially those from Italy and Spain. The process of understanding and successfully aligning with the rigors of the Western market economy lasted until 1999.

The fifth stage (1998-2018) - The period of revitalization through successful privatization. The process begins in 1998. One of the most difficult problems the company faced was the problem of debts that prevented the release of resources to make investments.

Becoming the majority shareholder (69.96%), the Italian consortium C.I.MU. was instrumental in establishing a portfolio of orders and more. Debts are paid off, investments are made in order to increase production, to improve the quality of cast parts and for the ecological rehabilitation.

Sixth stage (2019-prezent) - The pandemic was one of the triggering events of economic uncertainty and vulnerability. The situation was further aggravated by the war in Ukraine which generated the energy crisis and new economic problems worldwide. These unprecedented circumstances have forced companies to rethink their strategies and draw up a quick action plan. Despite all the difficulties encountered, Saturn continued its trajectory towards development and assimilation of new technologies, through an important program of investments in equipment, machines and installations.